3D Printing

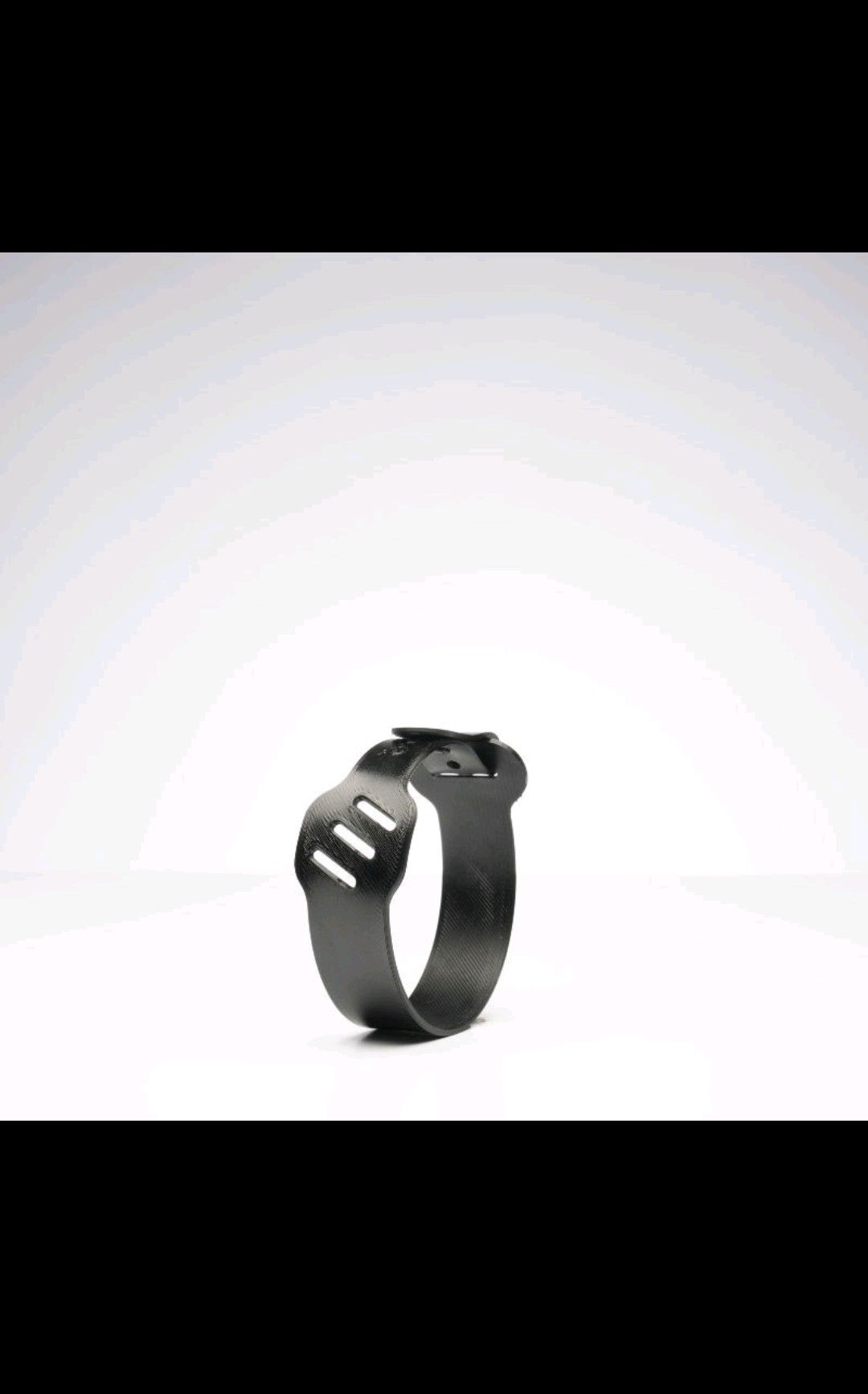

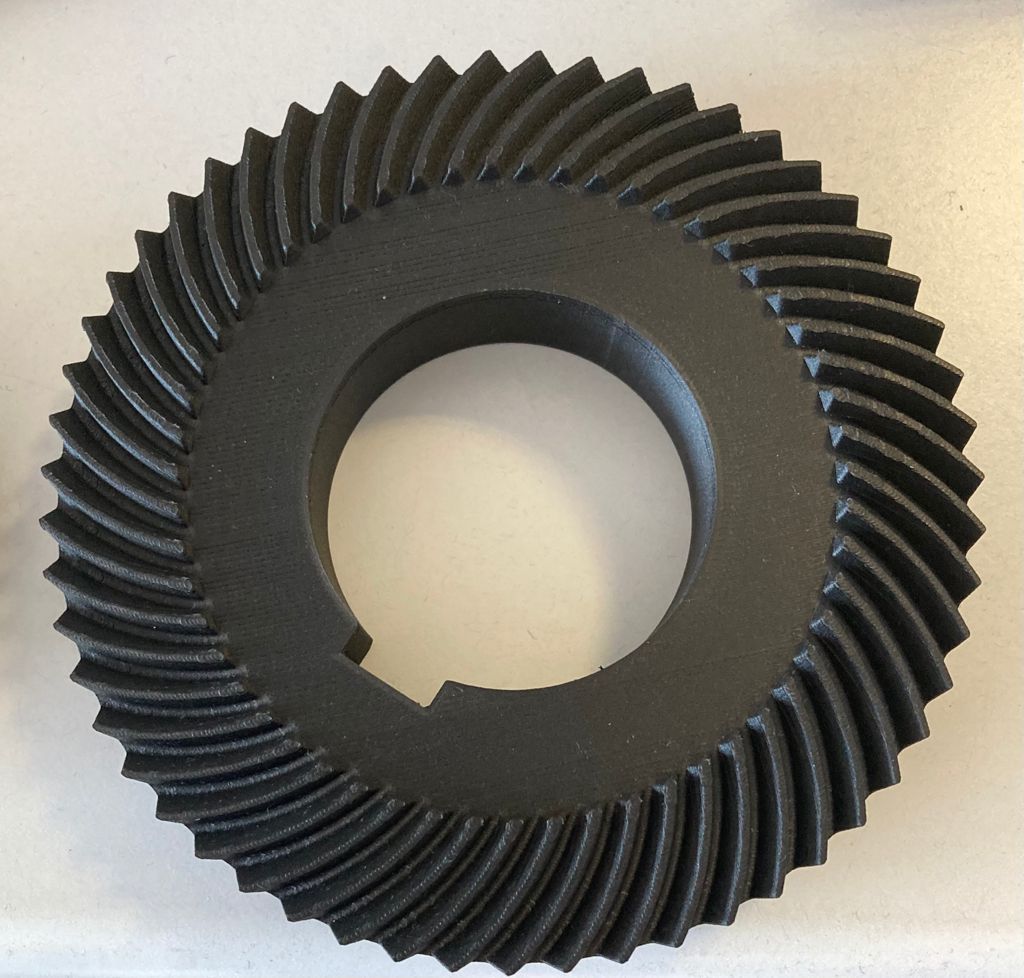

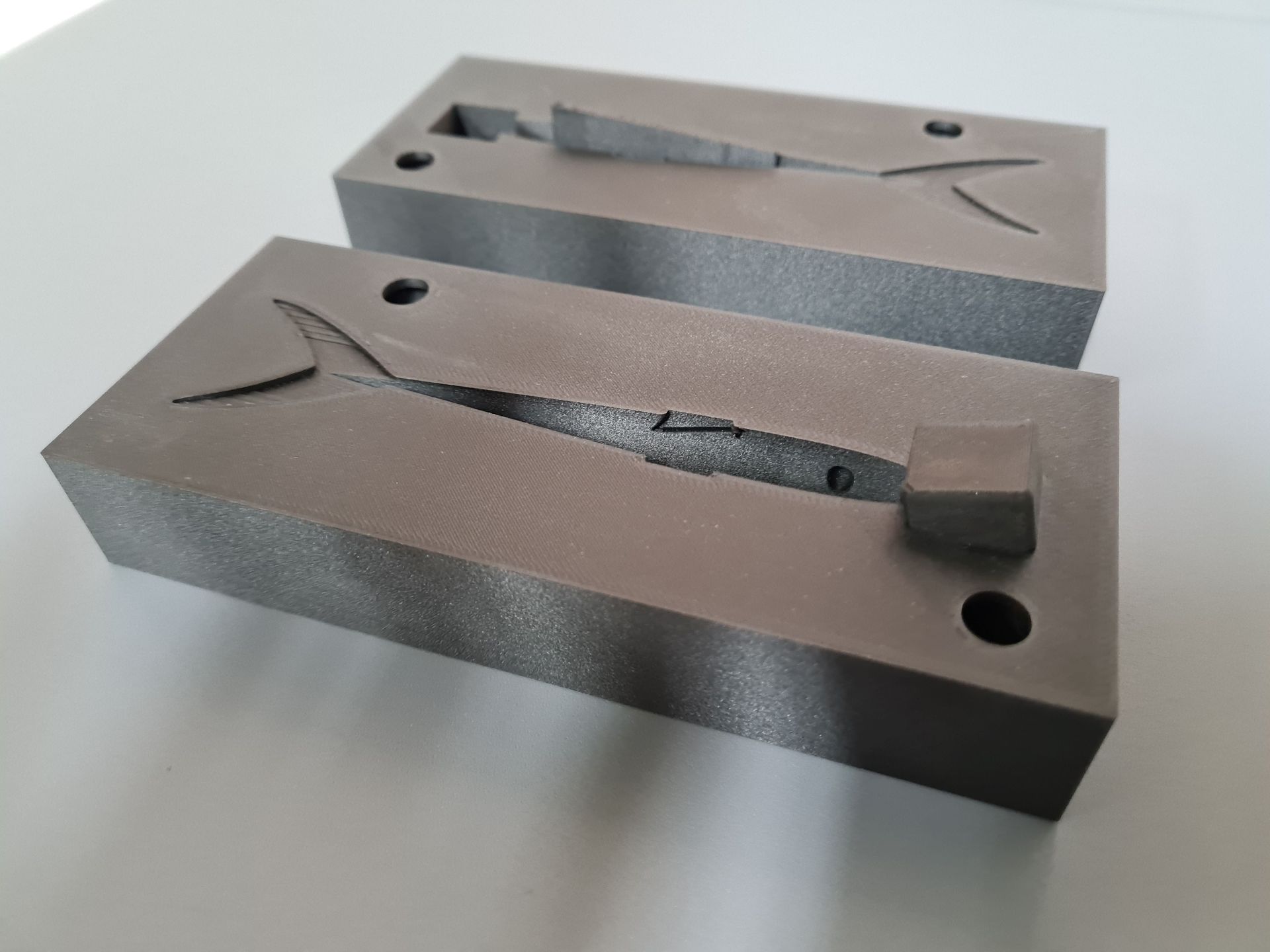

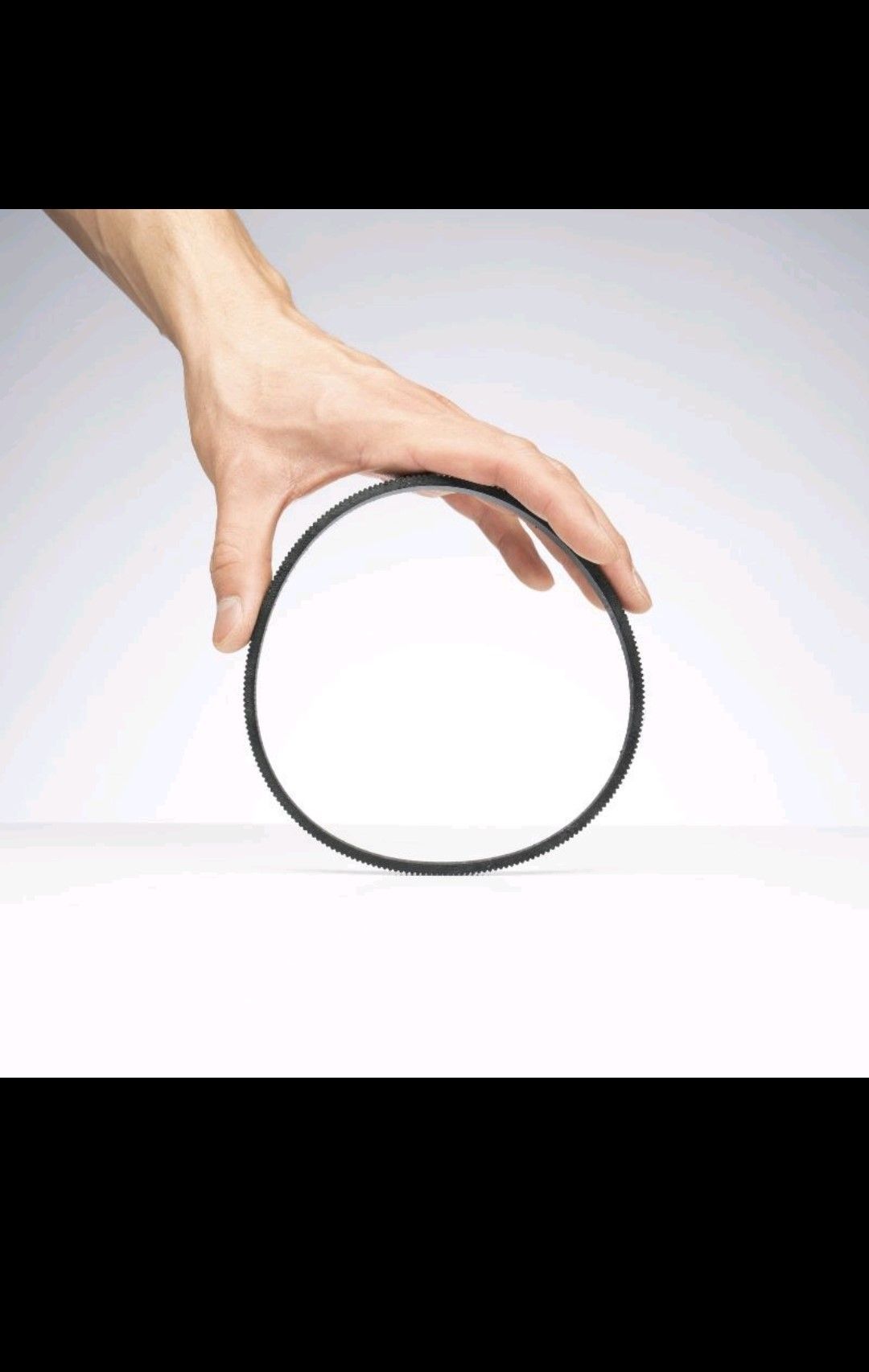

Structural components reinforced with carbon fibre, Kevlar and continuous glass

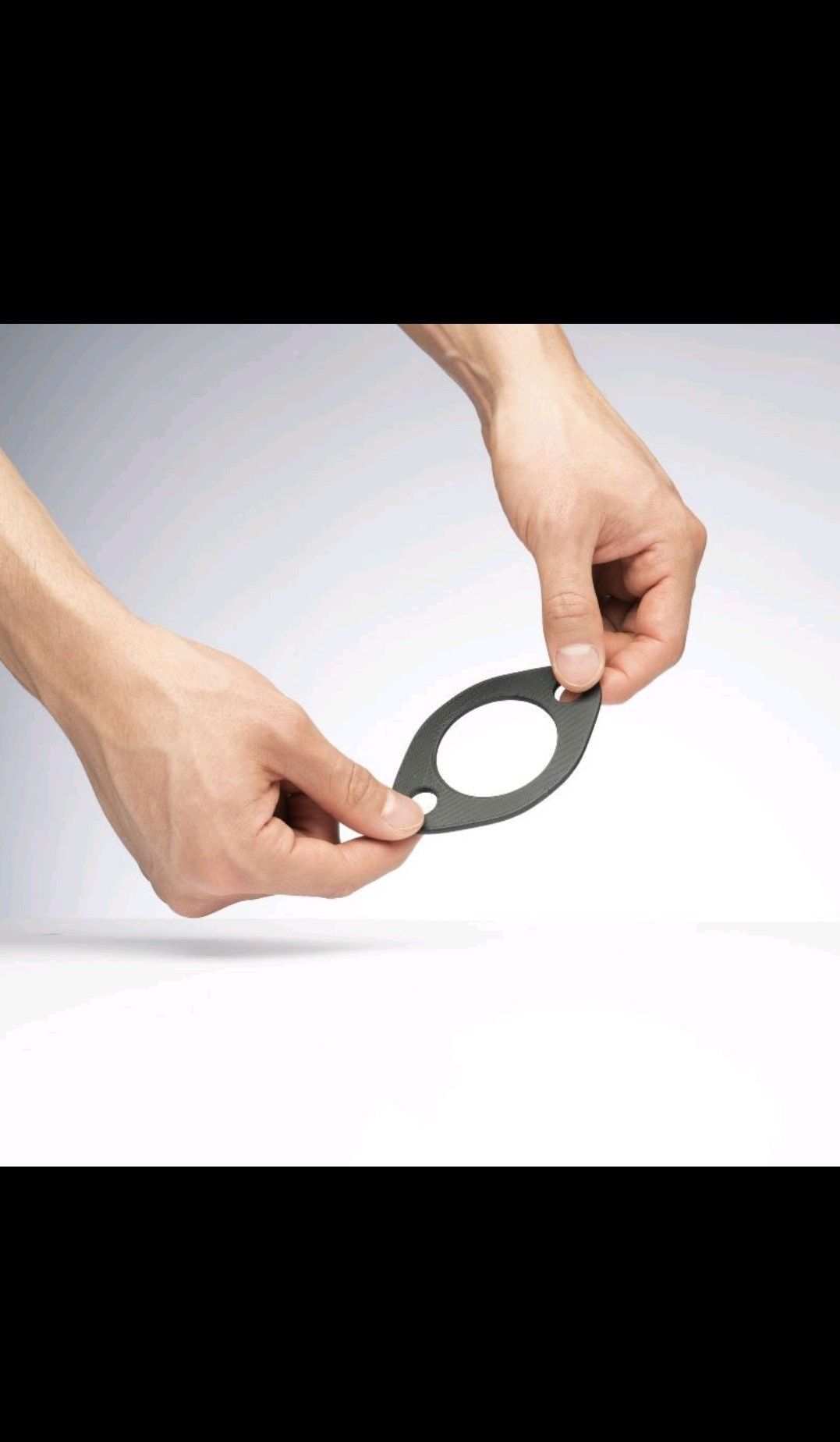

We are an innovative company that has found a way to use 3D printing technology to create carbon fibre items. This process is revolutionary in the field of carbon component production as it eliminates the need for expensive and complex moulds. In addition, 3D printing technology allows each part to be easily customised to meet individual customer requirements. Thanks to the use of 3D printing, we offer lightweight, durable and high-quality products that can be used in a wide range of applications.

Markforged 3D printer

The components moulded with this new technology will be carbon powder filled nylon PA6

with continuous carbon fibre reinforcement inside. The printer is therefore equipped with 2 nozzles: one that

extrudes the plastic and the other that inserts the continuous carbon filament inside the plastic matrix.

The result is a component made from a plastic matrix and with carbon fibre inside, like that

autoclave. The component will then be structural and can withstand very high loads.

Its mechanical strength is greater than aluminium itself.

The components can therefore be made in order to test them under high loads and verify their use.

The stapler has the ability to deposit both carbon and glass fibre and Kevlar inside the component.

Components

- Designed for heavy workloads (24/7 operation);

- Working volume 330 x 270 x 200 mm;

- Resolution up to 50 µm;

- Laser-assisted plane levelling;

- Active dimensional control, using laser micrometer.

- CFR (Continuous Fibre Reinforcement) the result is a composite material with CONTINUOUS FIBRE reinforcement.

Curves

Stress-strain curves

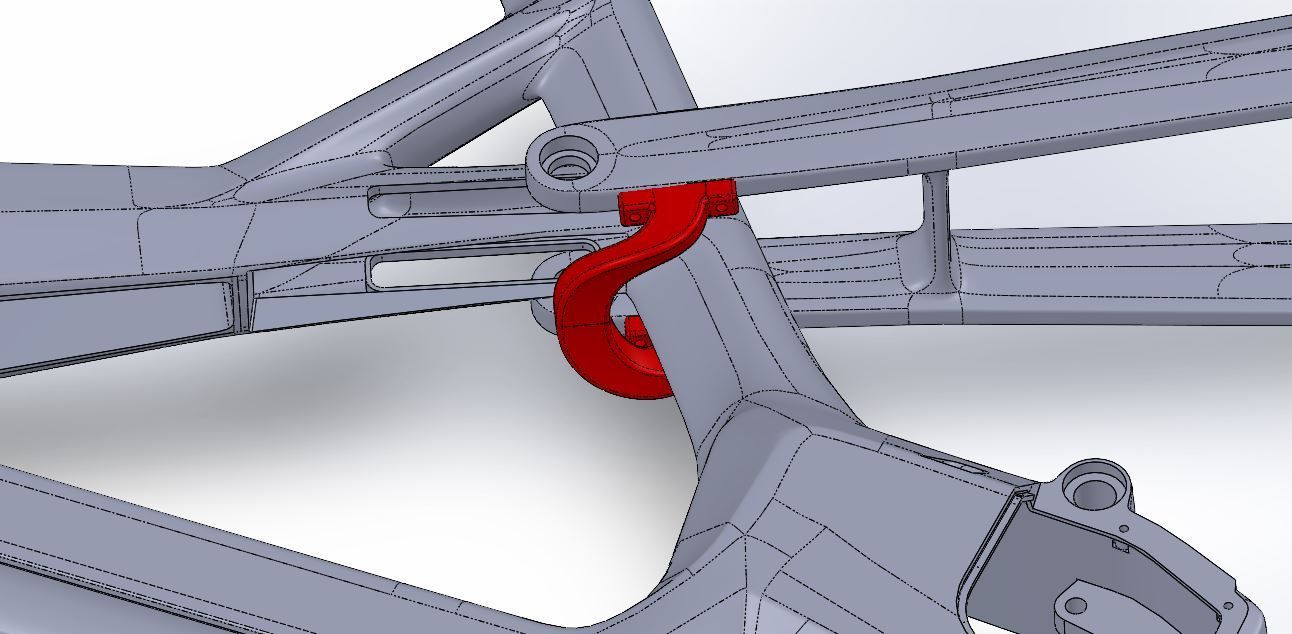

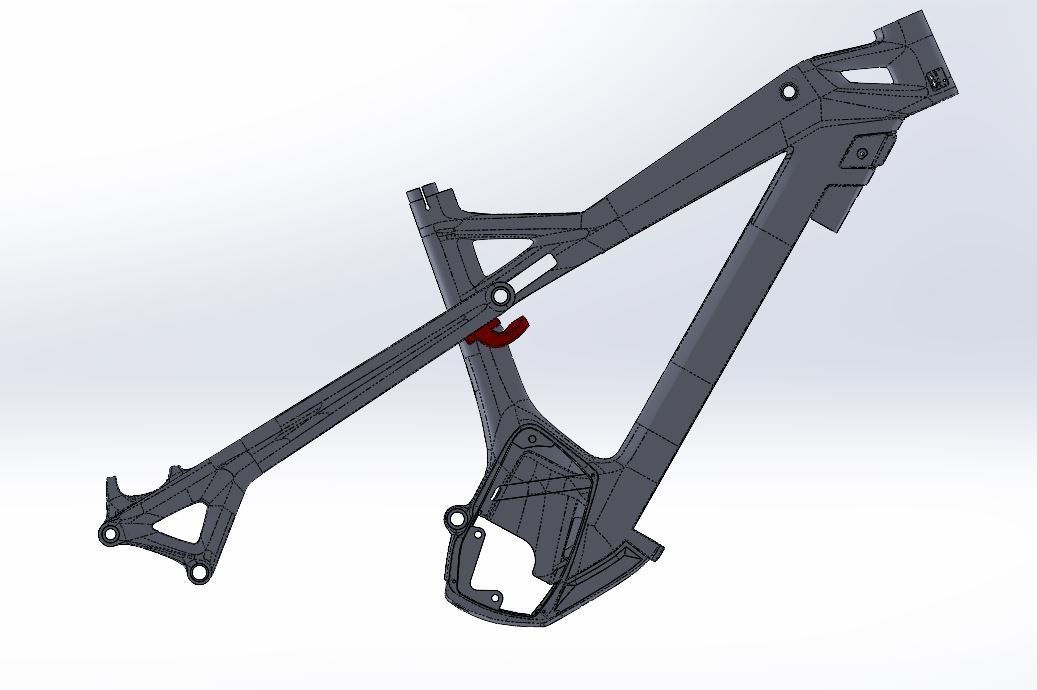

Applications

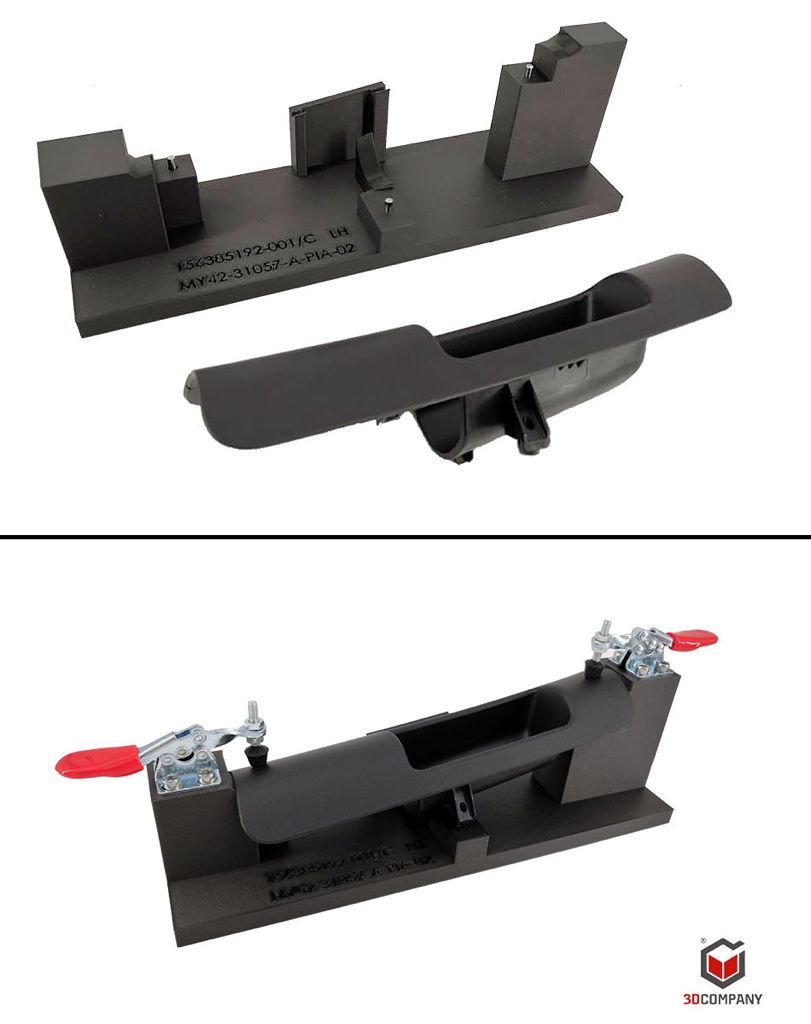

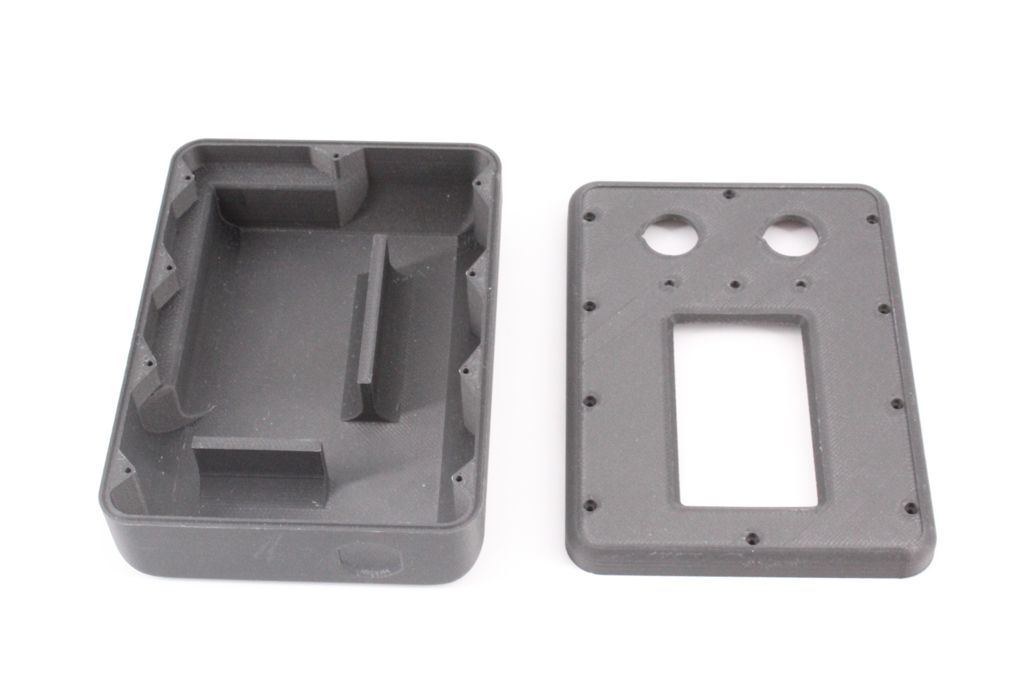

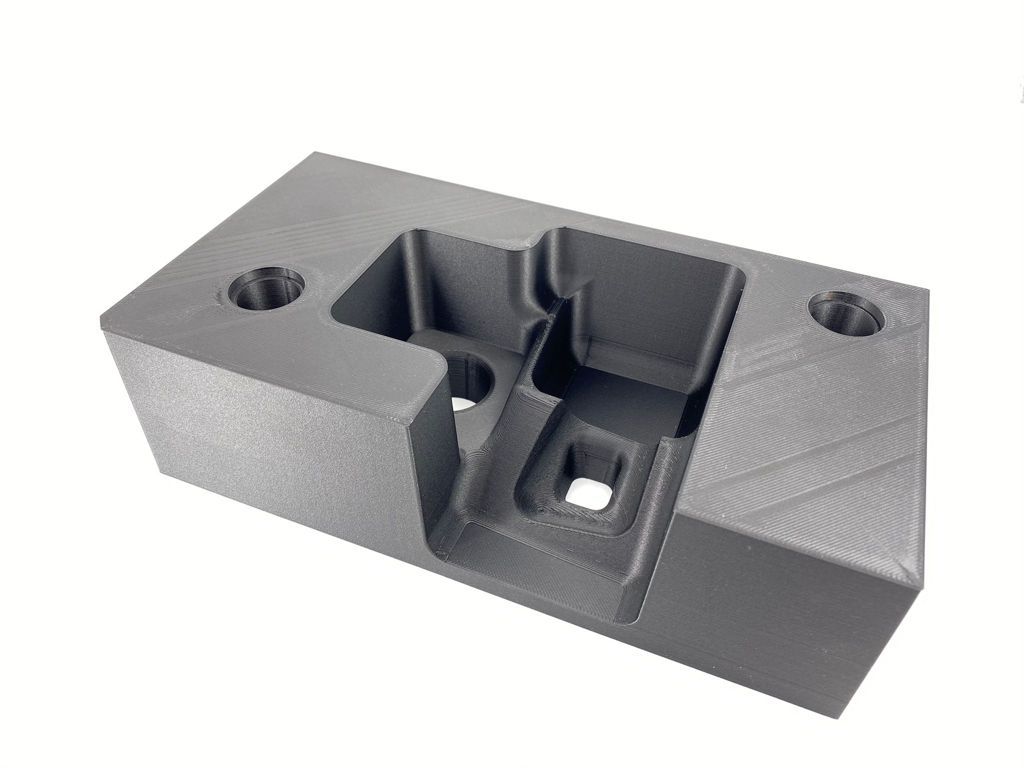

- Control gauges;

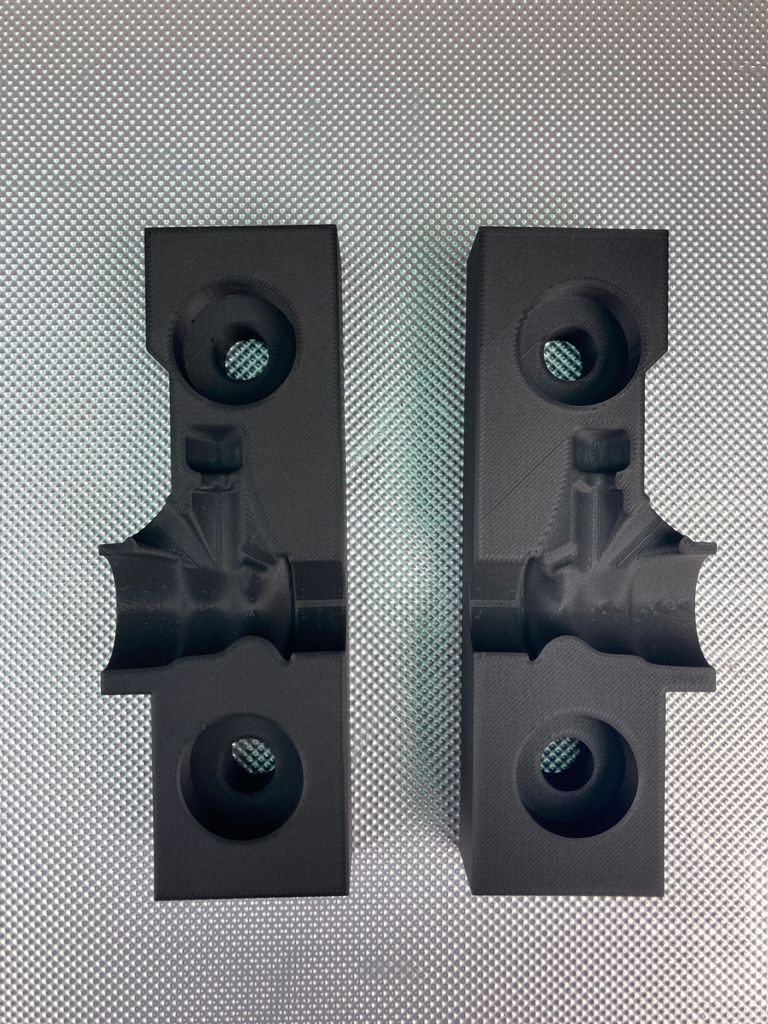

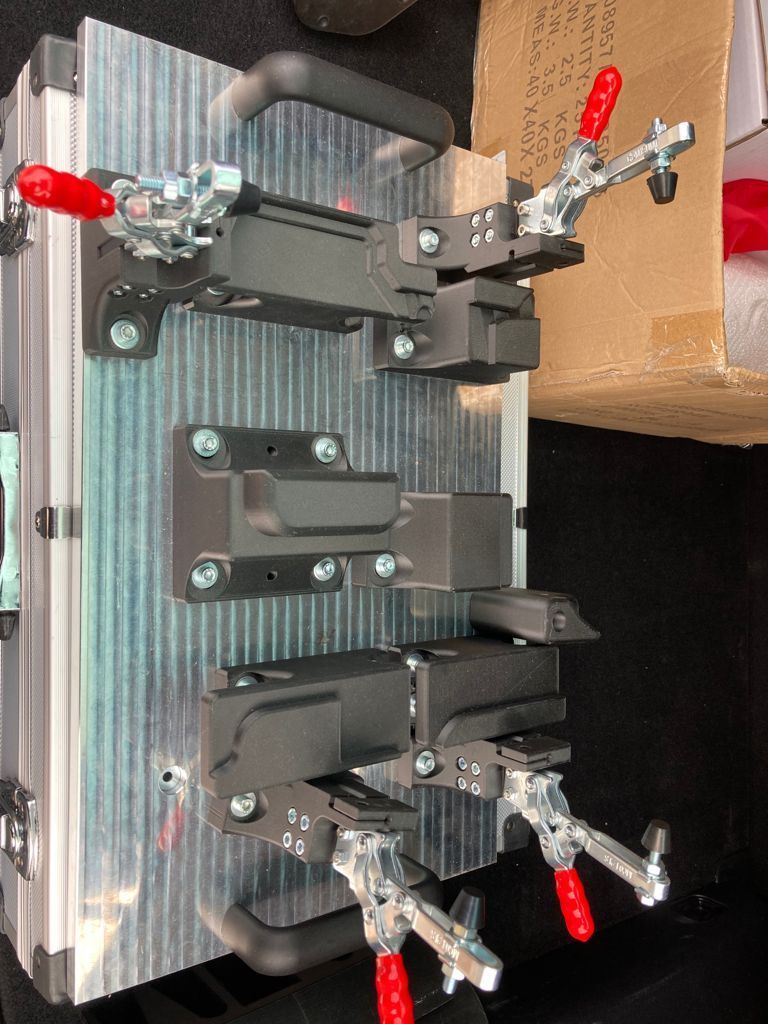

- Workpiece gripping jaws;

- Customised positions;

- Bodywork clamps (auto motive);

- Biomedical applications (FR);

- Electronic applications (FR);

- Carbon moulding autoclave moulds;

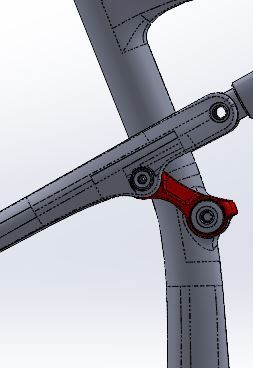

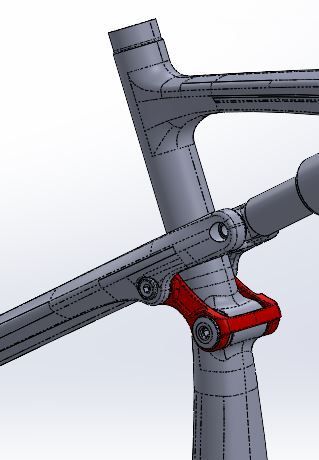

- Fixing brackets;

- Applications where traditional production fails or is too costly.