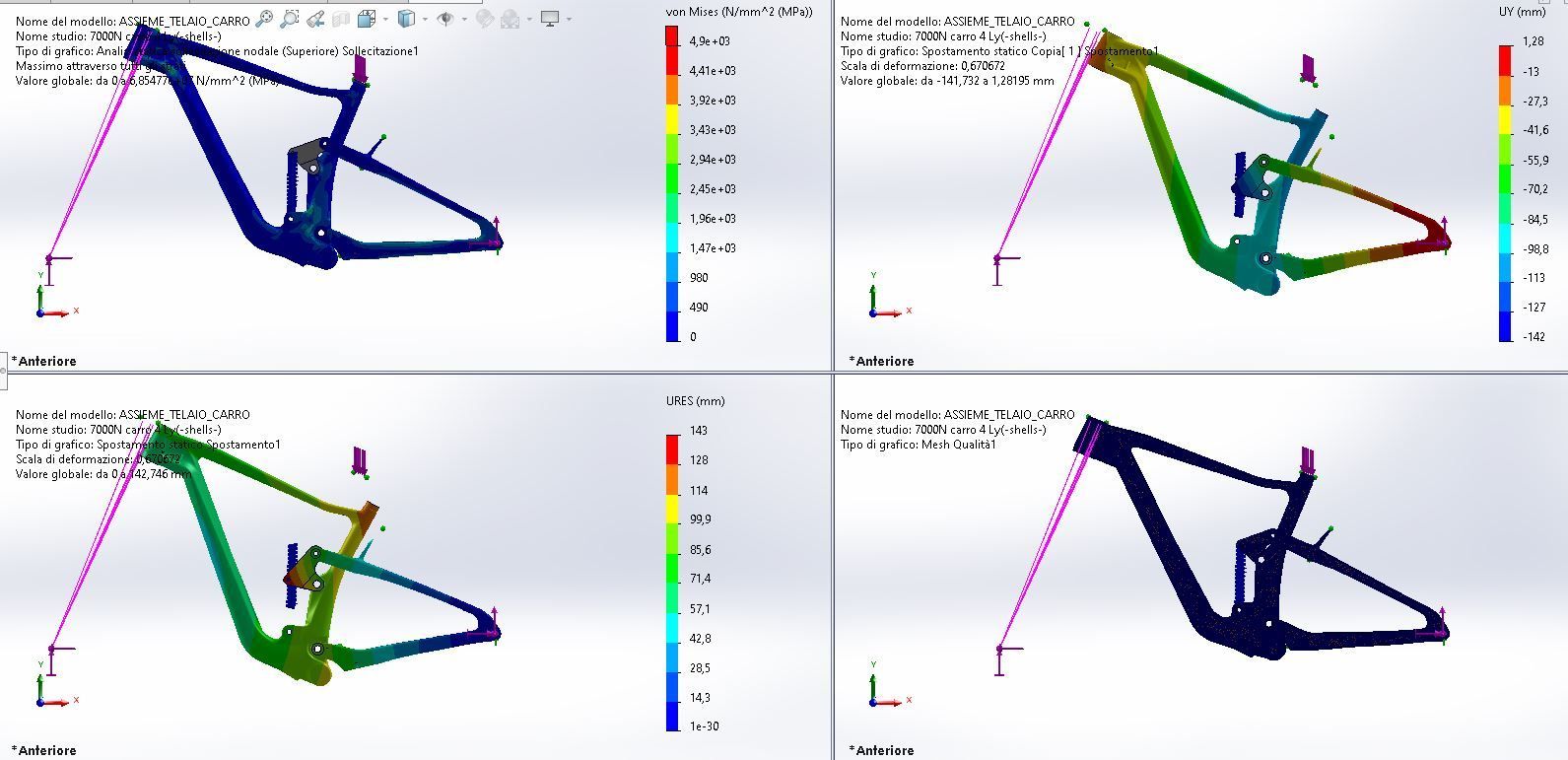

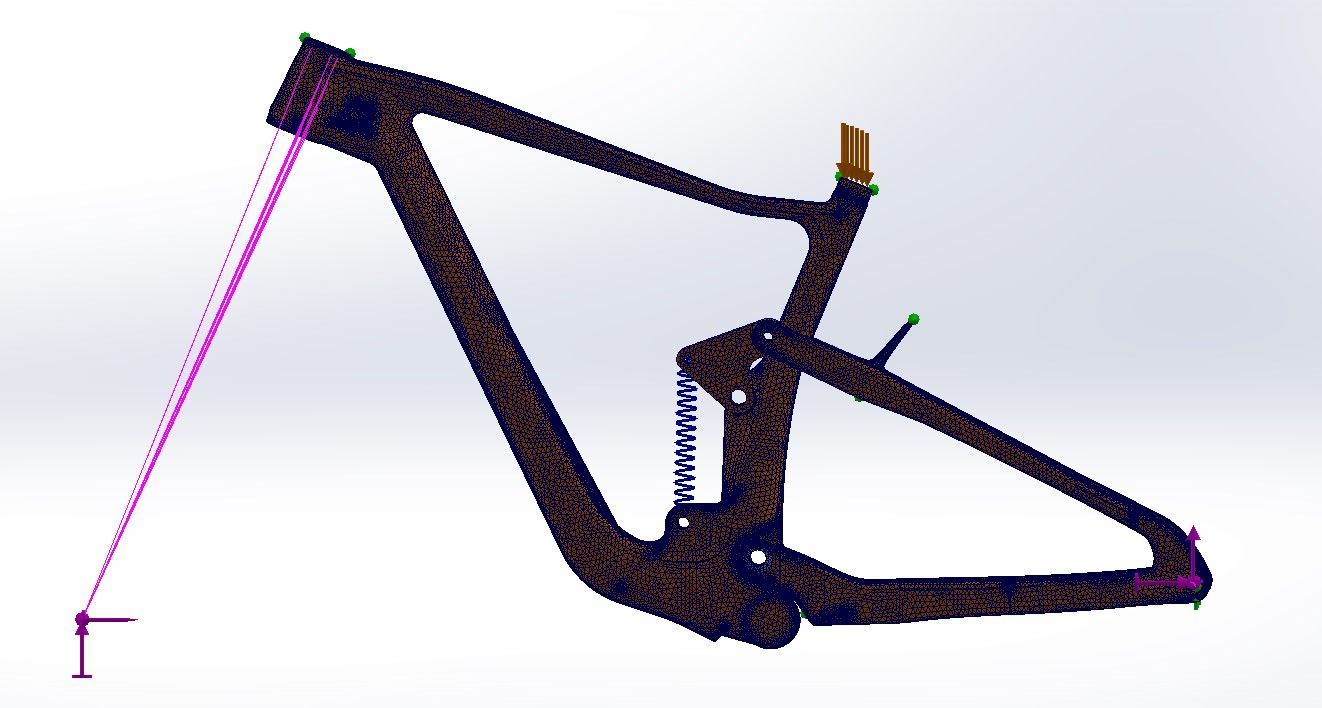

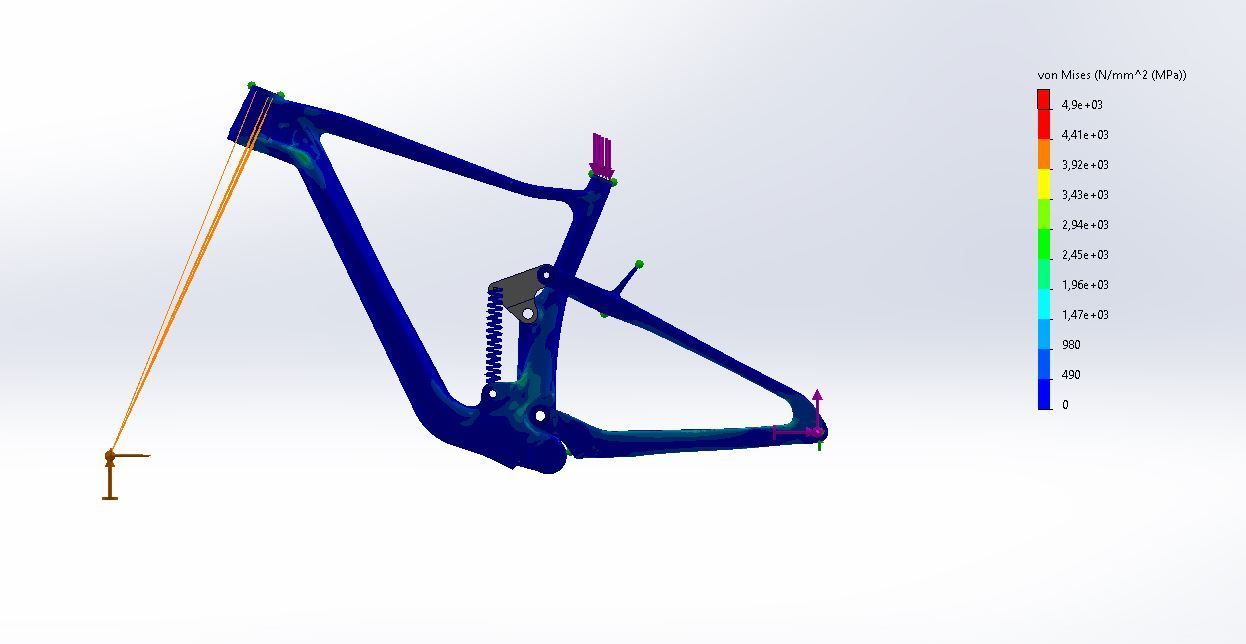

Finite element analysis

Finite element analysis, also known as FEM, is one of the most advanced simulation techniques available today, applicable to many fields of engineering. Thanks to this methodology, it is possible to describe a real system in a highly accurate and reliable manner, allowing the most relevant physical quantities to be obtained quickly. These include displacements, temperatures, stresses, deformations and many more. FEM is fundamental in structural analysis, mechanical engineering and aerospace applications, as well as in many other fields that require the evaluation of similar problems. Thanks to this technique, increasingly accurate and realistic simulations can be carried out, thus providing highly reliable results to meet increasingly stringent design requirements.

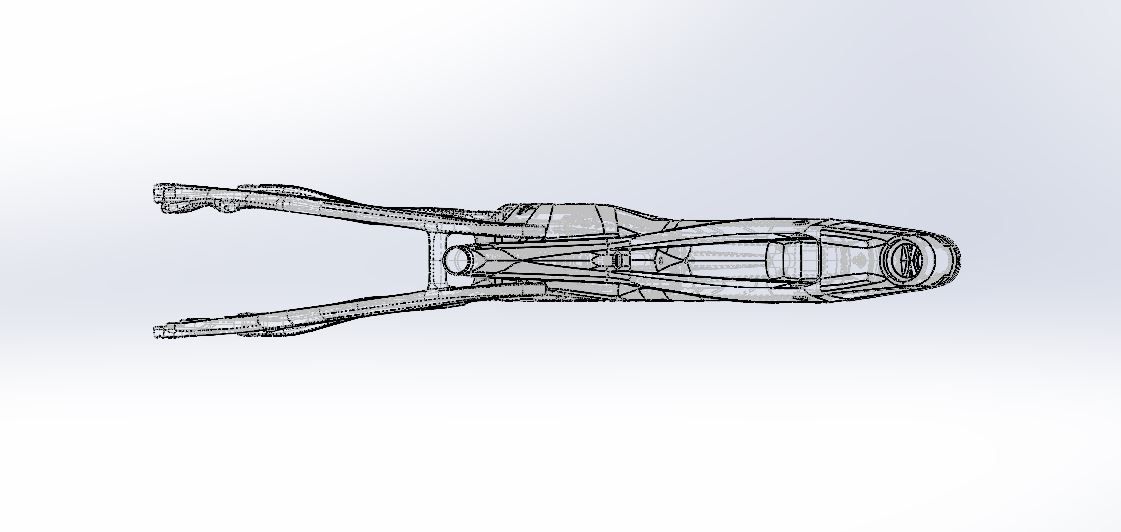

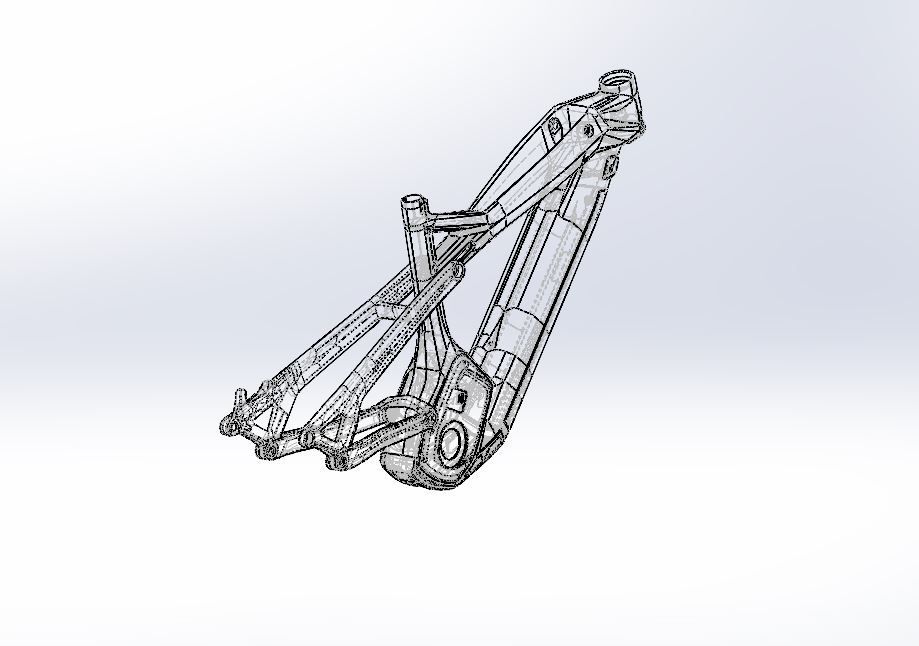

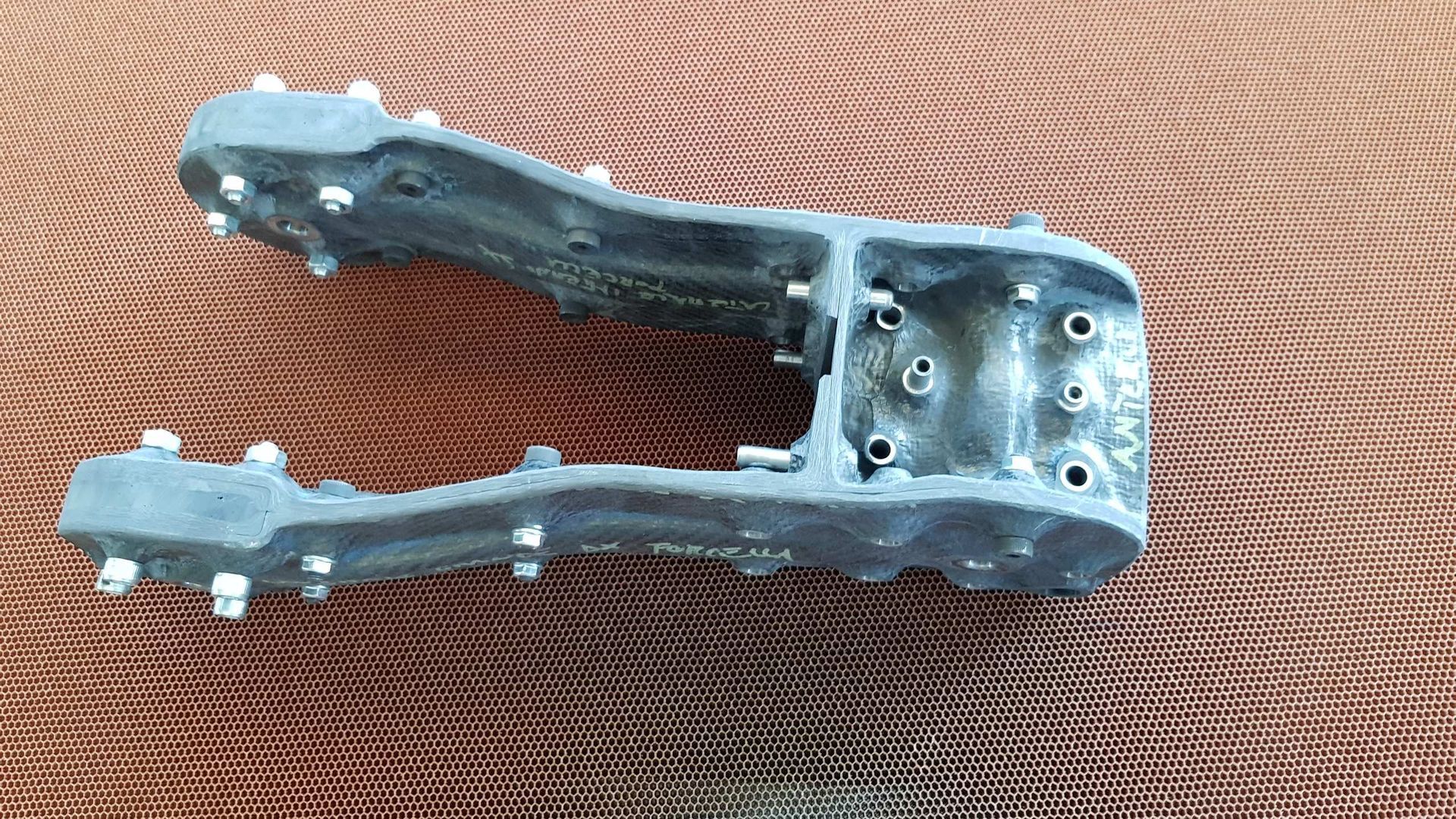

MTB monocoque frame + rear carriage

- 3D cad design

- Fem analysis

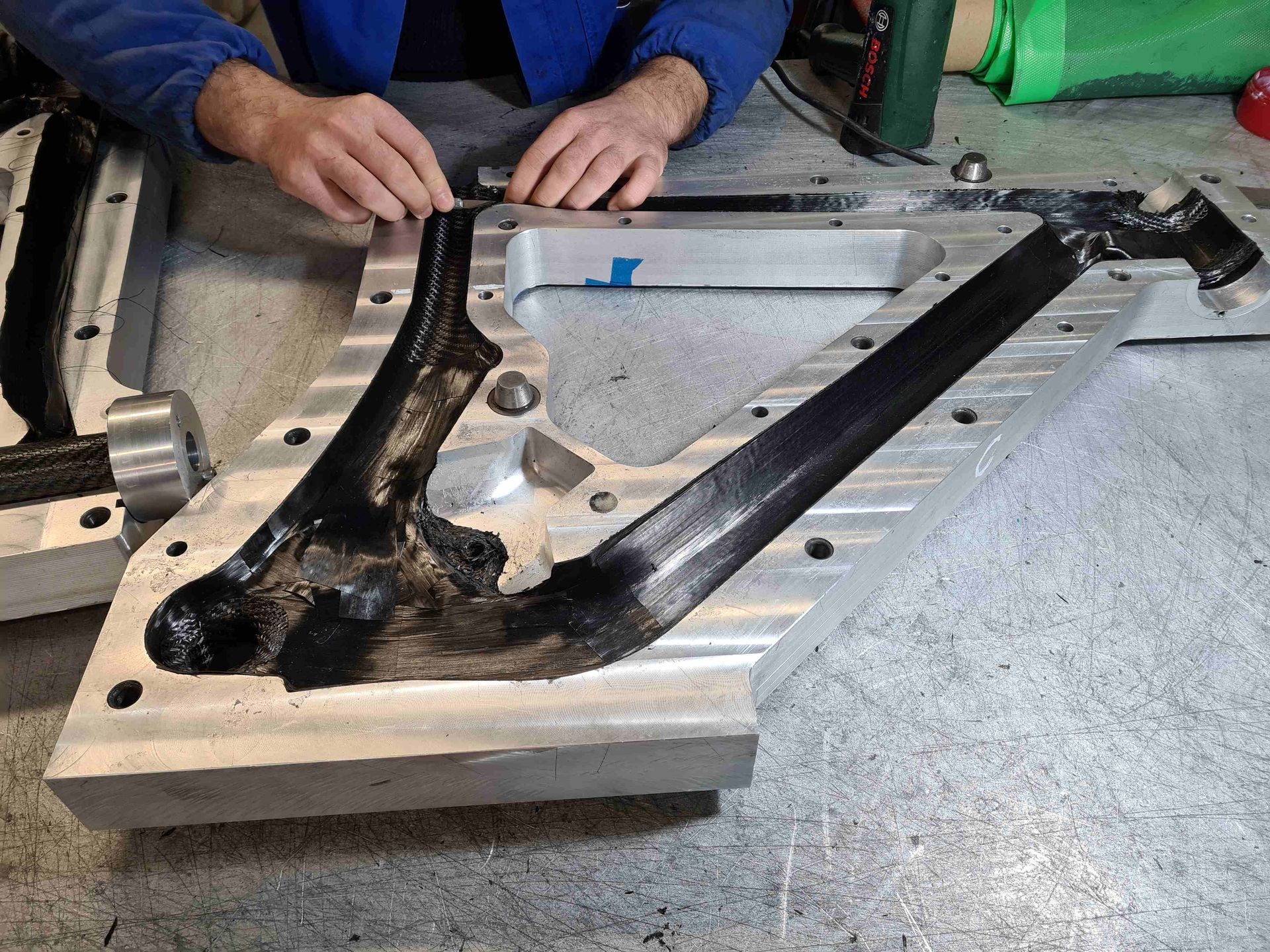

- Aluminium mould manufacture FRAME AND REAR CARRIAGE UNIT

- Production of monocoque frame and rear undercarriage for MTBs

The frame and carriage are fully carbon laminated using the 5 bar pressure autoclave process.

There is no gluing or additional banding.

The mechanical strength is clearly above a glued or wrapped frame.

The same is true for the rear carriage, which is also built in monolithic form and has directly embedded bearings and fasteners.

of the bearings and fasteners.

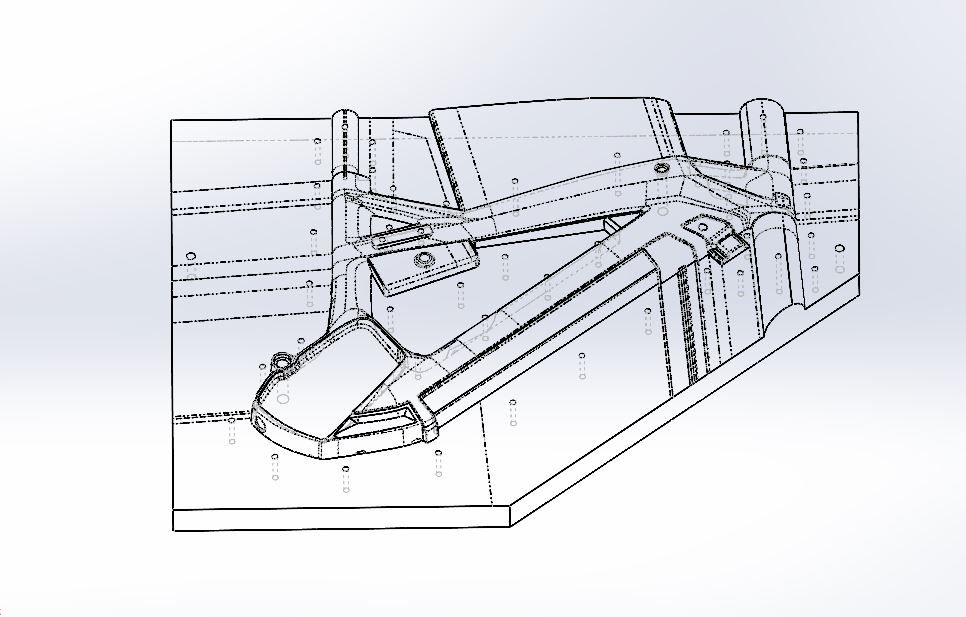

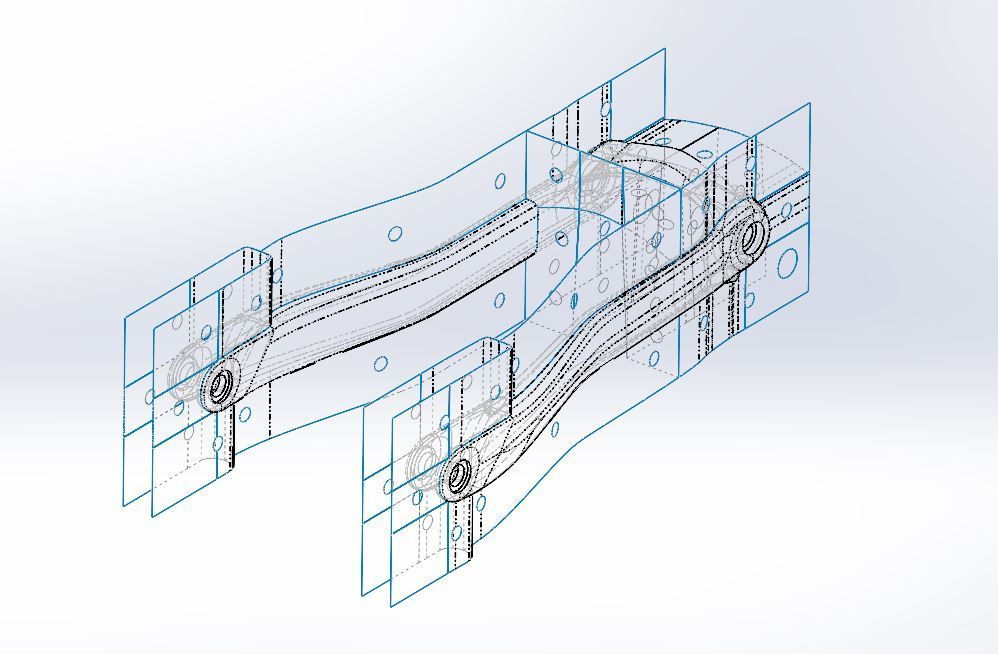

Monocoque electric bike frame + rear carriage

- 3D cad design

- FEM analysis

- Production of carbon frame and wagon moulds

- Production of monocoque frame and rear undercarriage

The frame and rear undercarriage is monocoque laminated in an autoclave at 5 bar pressure.

There is no gluing or wrapping.

The mechanical resistance is high and clearly superior to any wrapped frame or wagon.